Uglerod polat Hex Bolt Din 933

| Önümleriň ady | CARBON STEEL HEX BOLT DIN 933 / ISO4017 |

| Standart | DIN, ASTM / ANSI JIS EN ISO, AS, GB |

| Baha | Polat derejesi: DIN: Gr.4.6,4.8,5.6,5.8,8.8,10.9,12.9; SAE: Gr.2,5,8; ASTM: 307A, A325, A490, |

| Tamamlamak | Sink (Sary, Ak, Gök, Gara), Hop Dip Galvanizlenen (HDG), Gara Oksid, Geomet, Dakroment, anodizasiýa, Nikel örtülen, Sink-Nikel örtülen |

| Önümçilik prosesi | M2-M24: Sowuk doňmak, M24-M100 gyzgyn ýasama, Custöriteleşdirilen berkitme üçin enjam we CNC |

| Custöriteleşdirilen önümleriň wagty | 30-60 gün, |

| Adaty berkidiji üçin mugt nusgalar | |

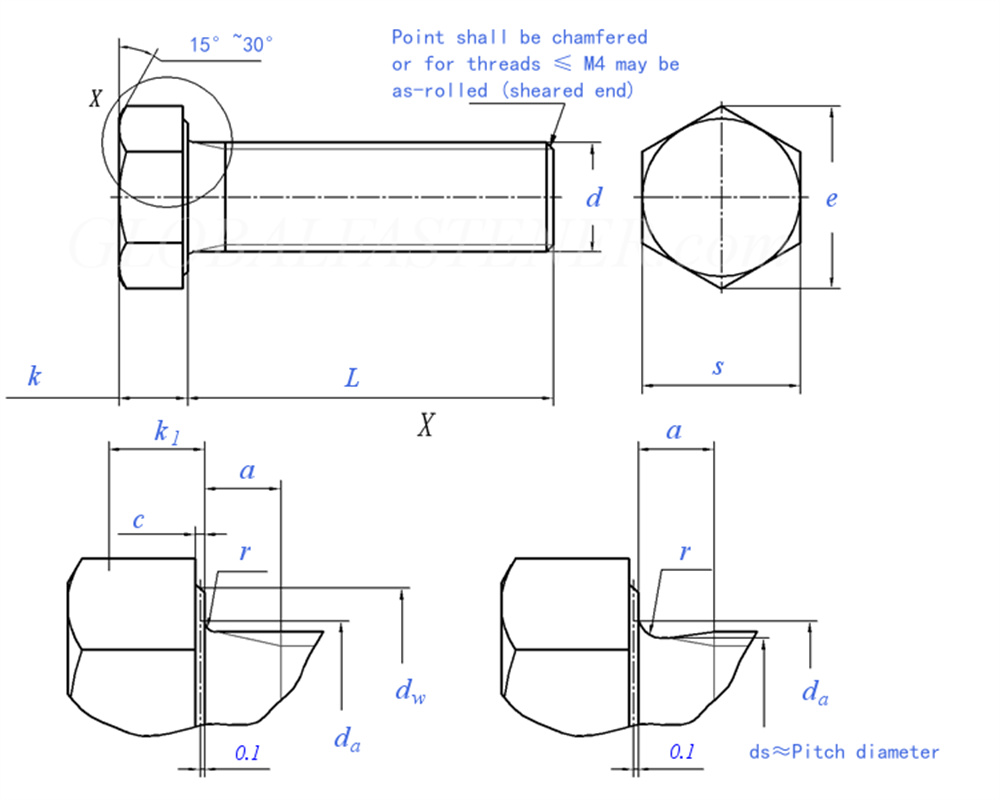

| Buraw sapak | M1.6 | M2 | M2.5 | M3 | (M3.5) | M4 | M5 | M6 | (M7) | M8 | M10 | M12 | ||

| P | Pit | 0.35 | 0.4 | 0.45 | 0,5 | 0.6 | 0.7 | 0.8 | 1 | 1 | 1.25 | 1.5 | 1.75 | |

| a | iň ýokary | 1.05 | 1.2 | 1.35 | 1.5 | 1.8 | 2.1 | 2.4 | 3 | 3 | 4 | 4.5 | 5.3 | |

| min | 0.35 | 0.4 | 0.45 | 0,5 | 0.6 | 0.7 | 0.8 | 1 | 1 | 1.25 | 1.5 | 1.75 | ||

| c | iň ýokary | 0.25 | 0.25 | 0.25 | 0.4 | 0.4 | 0.4 | 0,5 | 0,5 | 0.6 | 0.6 | 0.6 | 0.6 | |

| min | 0.1 | 0.1 | 0.1 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | ||

| da | iň ýokary | 2 | 2.6 | 3.1 | 3.6 | 4.1 | 4.7 | 5.7 | 6.8 | 7.8 | 9.2 | 11.2 | 13.7 | |

| dw | A synp | min | 2.27 | 3.07 | 4.07 | 4.57 | 5.07 | 5.88 | 6.88 | 8.88 | 9.63 | 11.63 | 14.63 | 16.63 |

| B synp | min | 2.3 | 2.95 | 3.95 | 4.45 | 4.95 | 5.74 | 6.74 | 8.74 | 9.47 | 11.47 | 14.47 | 16.47 | |

| e | A synp | min | 3.41 | 4.32 | 5.45 | 6.01 | 6.58 | 7.66 | 8.79 | 11.05 | 12.12 | 14.38 | 17.77 | 20.03 |

| B synp | min | 3.28 | 4.18 | 5.31 | 5.88 | 6.44 | 7.5 | 8.63 | 10.89 | 11.94 | 14.2 | 17.59 | 19.85 | |

| k | Nominal ululygy | 1.1 | 1.4 | 1.7 | 2 | 2.4 | 2.8 | 3.5 | 4 | 4.8 | 5.3 | 6.4 | 7.5 | |

| A synp | iň ýokary | 1.225 | 1.525 | 1.825 | 2.125 | 2.525 | 2.925 | 3.65 | 4.15 | 4.95 | 5.45 | 6.58 | 7.68 | |

| min | 0.975 | 1.275 | 1.575 | 1.875 | 2.275 | 2.675 | 3.35 | 3.85 | 4.65 | 5.15 | 6.22 | 7.32 | ||

| B synp | iň ýokary | 1.3 | 1.6 | 1.9 | 2.2 | 2.6 | 3 | 3.74 | 4.24 | 5.04 | 5.54 | 6.69 | 7.79 | |

| min | 0.9 | 1.2 | 1.5 | 1.8 | 2.2 | 2.6 | 3.26 | 3.76 | 4.56 | 5.06 | 6.11 | 7.21 | ||

| k1 | A synp | min | 0.68 | 0.89 | 1.1 | 1.31 | 1.59 | 1.87 | 2.35 | 2.7 | 3.26 | 3.61 | 4.35 | 5.12 |

| B synp | min | 0.63 | 0.84 | 1.05 | 1.26 | 1.54 | 1.82 | 2.28 | 2.63 | 3.19 | 3.54 | 4.28 | 5.05 | |

| r | min | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 0.2 | 0.25 | 0.25 | 0.4 | 0.4 | 0.6 | |

| s | max = nominal ululygy | 3.2 | 4 | 5 | 5.5 | 6 | 7 | 8 | 10 | 11 | 13 | 16 | 18 | |

| A synp | min | 3.02 | 3.82 | 4.82 | 5.32 | 5.82 | 6.78 | 7.78 | 9.78 | 10.73 | 12.73 | 15.73 | 17.73 | |

| B synp | min | 2.9 | 3.7 | 4.7 | 5.2 | 5.7 | 6.64 | 7.64 | 9.64 | 10.57 | 12.57 | 15.57 | 17.57 | |

| Buraw sapak | (M14) | M16 | (M18) | M20 | (M22) | M24 | (M27) | M30 | (M33) | M36 | (M39) | M42 | ||

| P | Pit | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | |

| a | iň ýokary | 6 | 6 | 7.5 | 7.5 | 7.5 | 9 | 9 | 10.5 | 10.5 | 12 | 12 | 13.5 | |

| min | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | ||

| c | iň ýokary | 0.6 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 1 | 1 | |

| min | 0.15 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.3 | 0.3 | ||

| da | iň ýokary | 15.7 | 17.7 | 20.2 | 22.4 | 24.4 | 26.4 | 30.4 | 33.4 | 36.4 | 39.4 | 42.4 | 45.6 | |

| dw | A synp | min | 19.64 | 22.49 | 25.34 | 28.19 | 31.71 | 33.61 | - | - | - | - | - | - |

| B synp | min | 19.15 | 22 | 24.85 | 27.7 | 31.35 | 33.25 | 38 | 42.75 | 46.55 | 51.11 | 55.86 | 59.95 | |

| e | A synp | min | 23.36 | 26.75 | 30.14 | 33.53 | 37.72 | 39.98 | - | - | - | - | - | - |

| B synp | min | 22.78 | 26.17 | 29.56 | 32.95 | 37.29 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 71.3 | |

| k | Nominal ululygy | 8.8 | 10 | 11.5 | 12.5 | 14 | 15 | 17 | 18.7 | 21 | 22.5 | 25 | 26 | |

| A synp | iň ýokary | 8.98 | 10.18 | 11.715 | 12.715 | 14.215 | 15.215 | - | - | - | - | - | - | |

| min | 8.62 | 9.82 | 11.285 | 12.285 | 13.785 | 14.785 | - | - | - | - | - | - | ||

| B synp | iň ýokary | 9.09 | 10.29 | 11.85 | 12.85 | 14.35 | 15.35 | 17.35 | 19.12 | 21.42 | 22.92 | 25.42 | 26.42 | |

| min | 8.51 | 9.71 | 11.15 | 12.15 | 13.65 | 14.65 | 16.65 | 18.28 | 20.58 | 22.08 | 24.58 | 25.58 | ||

| k1 | A synp | min | 6.03 | 6.87 | 7.9 | 8.6 | 9.65 | 10.35 | - | - | - | - | - | - |

| B synp | min | 5.96 | 6.8 | 7.81 | 8.51 | 9.56 | 10.26 | 11.66 | 12.8 | 14.41 | 15.46 | 17.21 | 17.91 | |

| r | min | 0.6 | 0.6 | 0.6 | 0.8 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | 1.2 | |

| s | max = nominal ululygy | 21 | 24 | 27 | 30 | 34 | 36 | 41 | 46 | 50 | 55 | 60 | 65 | |

| A synp | min | 20.67 | 23.67 | 26.67 | 29.67 | 33.38 | 35.38 | - | - | - | - | - | - | |

| B synp | min | 20.16 | 23.16 | 26.16 | 29.16 | 33 | 35 | 40 | 45 | 49 | 53.8 | 58.8 | 63.1 | |

| Buraw sapak | (M45) | M48 | (M52) | M56 | (M60) | M64 | ||||||||

| P | Pit | 4.5 | 5 | 5 | 5.5 | 5.5 | 6 | |||||||

| a | iň ýokary | 13.5 | 15 | 15 | 16.5 | 16.5 | 18 | |||||||

| min | 4.5 | 5 | 5 | 5.5 | 5.5 | 6 | ||||||||

| c | iň ýokary | 1 | 1 | 1 | 1 | 1 | 1 | |||||||

| min | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | ||||||||

| da | iň ýokary | 48.6 | 52.6 | 56.6 | 63 | 67 | 71 | |||||||

| dw | A synp | min | - | - | - | - | - | - | ||||||

| B synp | min | 64.7 | 69.45 | 74.2 | 78.66 | 83.41 | 88.16 | |||||||

| e | A synp | min | - | - | - | - | - | - | ||||||

| B synp | min | 76.95 | 82.6 | 88.25 | 93.56 | 99.21 | 104.86 | |||||||

| k | Nominal ululygy | 28 | 30 | 33 | 35 | 38 | 40 | |||||||

| A synp | iň ýokary | - | - | - | - | - | - | |||||||

| min | - | - | - | - | - | - | ||||||||

| B synp | iň ýokary | 28.42 | 30.42 | 33.5 | 35.5 | 38.5 | 40.5 | |||||||

| min | 27.58 | 29.58 | 32.5 | 34.5 | 37.5 | 39.5 | ||||||||

| k1 | A synp | min | - | - | - | - | - | - | ||||||

| B synp | min | 19.31 | 20.71 | 22.75 | 24.15 | 26.25 | 27.65 | |||||||

| r | min | 1.2 | 1.6 | 1.6 | 2 | 2 | 2 | |||||||

| s | max = nominal ululygy | 70 | 75 | 80 | 85 | 90 | 95 | |||||||

| A synp | min | - | - | - | - | - | - | |||||||

| B synp | min | 68.1 | 73.1 | 78.1 | 82.8 | 87.8 | 92.8 | |||||||

Aýratynlyklary we peýdalary

Uglerod polat Hex Bolt Din 933: Berkidiji zerurlyklaryňyzyň çözgüdi

Berkidmek barada aýdylanda, berk, ygtybarly we gurmak aňsat çözgüt isleýärsiňiz. Uglerod Polat Hex Bolt Din 933, köp sanly programmada ulanylyp bilinjek çydamly we köpugurly bolt hödürläp, ähli gutulara bellik edýär.

Qualityokary hilli uglerod polatdan ýasalan bu bolt, kyn şertlere, ýokary streslere we agyr ýüklere garşy durmak üçin niýetlenendir. Altyburçly kelle ygtybarly we berk laýyklygy üpjün edýär, sapak bolsa aňsat gurnamaga we aýyrmaga mümkinçilik berýär.

Uzynlygy 6mm-den 100mm-e çenli bolan bu bolt dürli taslamalara we talaplara laýyk dürli ölçeglerde elýeterlidir. Maşyn gurýarsyňyzmy, gurluş gurýarsyňyzmy ýa-da enjamlary berkidýärsiňizmi, bu bolt işi ýerine ýetirmek üçin zerur güýç we çydamlylyk hödürleýär.

Mundan başga-da, uglerod polat Hex Bolt Din 933 saklamak aňsat we wagtyň geçmegi bilen aňsatlaşmaýar. Bu, gurnandan soň birnäçe ýyllap netijeliligine bil baglap bilersiňiz.

Elýeterli we ýokary hilli bolt gözleýänler üçin bu uglerod polat bolt ajaýyp saýlawdyr. Diňe gymmat we çylşyrymly berkidiji çözgütleriň zerurlygyny aradan aýyrmak bilen çäklenmän, gymmatly wagtyňyzy we güýjüňizi tygşytlamak bilen gurmak we aýyrmak hem aňsat.

Gysgaça aýtsak, “Carbon Steel Hex Bolt Din 933” birnäçe amaly programmalarda ulanyp boljak ýokary ygtybarly we amaly berkidiji çözgütdir. Maksimum çydamlylyk we ulanmagyň aňsatlygy üçin döredilip, inersenerler, gurluşykçylar we DIY höwesjeňleri üçin saýlama bolýar. Haýsy taslamanyň üstünde işleýändigiňize garamazdan, ähli gutulara degip geçýän çözgüt hödürlemek üçin Carbon Steel Hex Bolt Din 933-e bil baglaň.